Mazak to Host Special San Francisco Event for Silicon Valley Shops

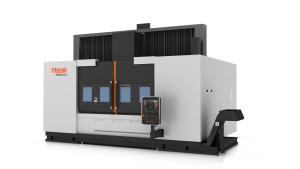

Mazak will host a special Discover More with Mazak™ Technology and Learning event at its San Francisco facility in Milpitas, California, March 15 – 16 from 10:00 a.m. to 4:00 p.m. The event will center on the particular needs of Silicon Valley shops as well as those of the local area manufacturing community in general.